This project aims to advance the understanding of the behaviour of shared anchors for offshore floating wind applications. The work is carried out as a joint effort between Delft University of Technology (DUT) and Deltares, leveraging the complementary capabilities of their geotechnical centrifuge facilities and disciplinary expertise. The centrifuge enables reduced-scale modelling of large-scale soil–structure interaction while preserving the stress-dependent nature of soil behaviour through an enhanced gravity field.

The first stage of the project focuses on the design, development, and commissioning of the required centrifuge hardware. This work is carried out independently at both facilities and includes the following scope:

Following validation, these systems will enable controlled simulation of the complex loading regimes generated by floating wind turbines, which are subjected to combined wind, wave, and current forces. Where appropriate, time-history load protocols will be incorporated to advance hybrid testing.

Within the joint DUT–Deltares research framework, a modelling-of-models approach is adopted, taking advantage of the size differences between the two centrifuges. Identical shared anchor models are tested in both facilities to enable direct comparison and cross-validation of results. This dual approach strengthens the scientific value of the findings and, once established, allows the study of varying prototype sizes across the facilities.

The experimental work is divided into two centrifuge campaigns. The first campaign focuses on the one-dimensional lateral response of wished-in-place (WIP) anchors installed under 1g conditions. The second campaign targets the dynamic installation of the foundation at elevated g-levels, followed by single- and multidirectional loading. The complementary nature of the DUT and Deltares setups thus provides broader and more reliable insight into the behaviour of shared anchors under multidirectional loading.

The wide range of existing centrifuge hardware and expertise further provides opportunities to broaden the research scope by investigating how installation processes influence the operational performance of shared anchors. This can be achieved either by exploring variability in the operational parameters of installation systems or by assessing different installation methods.

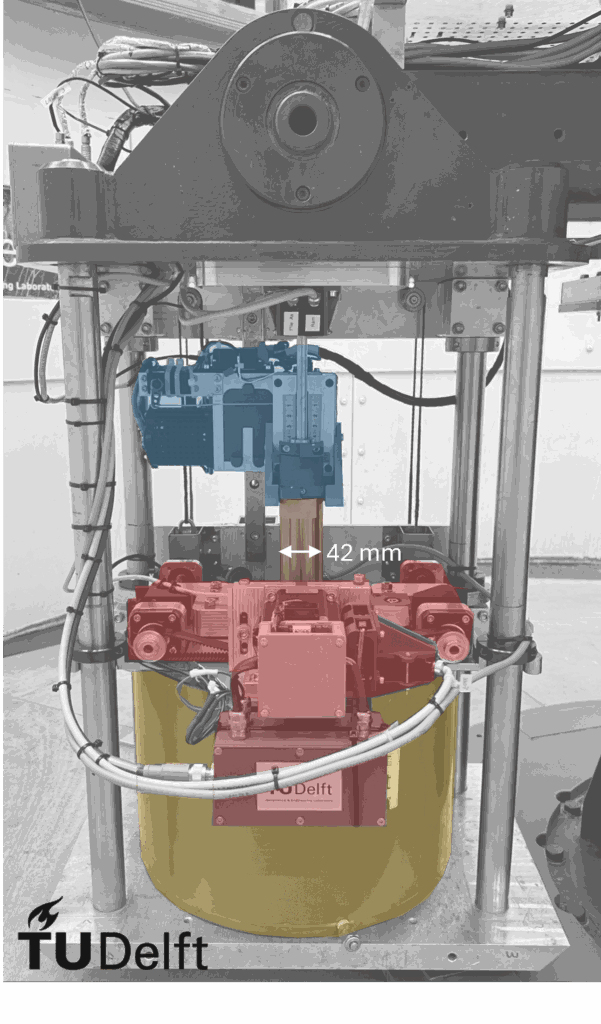

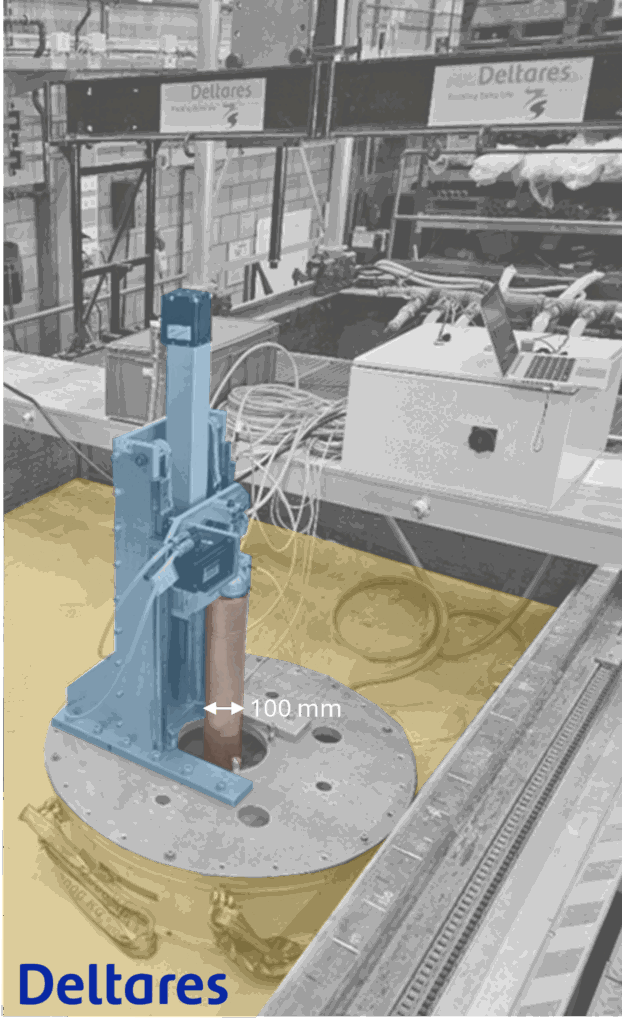

The figures below illustrate the current state of progress, showing (a) the impact hammer and single-directional loading setup as mounted in the centrifuge facility of DUT and (b) the validation of the impact hammer for centrifuge testing at Deltares.

Contact: T.O.Quinten@tudelft.nl

Accelerating innovations in offshore renewables through data-driven hybrid labs.

@2025 HybridLabs